Keeping your tractor's hydraulic system functioning smoothly is crucial for productivity and safety. A faulty hydraulic system can lead to costly repairs and downtime. Regular testing with a reliable hydraulic pressure test kit is the key to preventing these issues. This guide will help you select, use, and maintain the best kit for your needs. For more information on tractor hydraulic components, check out this helpful resource on tractor hydraulic cylinders.

Understanding Tractor Hydraulic Systems and Pressure Testing

Tractor hydraulic systems use pressurized fluid to power various components, including the lift arms, three-point hitch, and power steering. Regular pressure testing helps identify leaks, blockages, or other problems before they cause significant damage. Pressure testing allows for proactive maintenance, preventing costly breakdowns and ensuring optimal performance.

Types of Tractor Hydraulic Pressure Test Kits

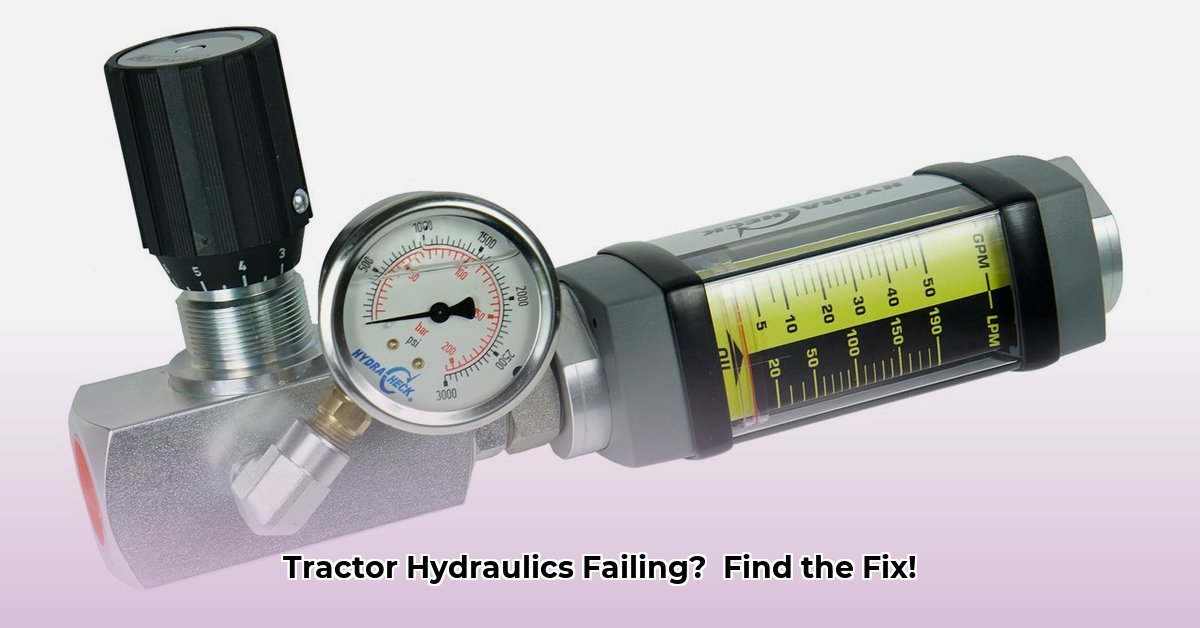

Several types of kits cater to different needs and budgets. The primary distinction lies between analog and digital gauges:

- Analog Gauges: These are simpler, typically more robust, and usually less expensive. They provide a direct visual reading of the pressure.

- Digital Gauges: These offer more precise readings and often include features like data logging and various measurement units. However, they can be more fragile and expensive.

Beyond this, consider the pressure range of the kit in relation to your tractor's hydraulic system specifications (found in your owner's manual). Incorrectly sized gauges can lead to inaccurate readings or damage. Finally, ensure the kit's connectors are compatible with your tractor's hydraulic ports.

Choosing the Right Kit: A Comparative Analysis

Selecting the appropriate kit depends on your needs and budget. Factors to consider include accuracy, durability, features, and price. High-accuracy gauges with a ±1% or better tolerance are preferable for critical applications. While more expensive, they provide crucial precision for precise diagnosis. Durability is crucial – look for corrosion-resistant materials and robust construction.

| Feature | Analog Gauge | Digital Gauge | Considerations |

|---|---|---|---|

| Accuracy | Generally less precise | Typically more precise | Higher accuracy is essential for precise diagnostics and preventative maintenance. |

| Cost | Lower upfront investment | Higher initial cost | Balance cost with the required accuracy and features. |

| Durability | Usually robust | Can be more sensitive to damage | Prioritize rugged construction for long-term use in demanding environments. |

| Features | Basic pressure display | Data logging, multiple units, backlight, etc. | Consider additional features based on your needs and the complexity of your hydraulic system. |

Expert Insight: "For most agricultural applications, a gauge with an accuracy of ±1% of full scale should be sufficient. However, for more critical systems or frequent use, a higher accuracy level of ±0.5% or better might be beneficial," states Dr. Emily Carter, Agricultural Engineering Professor, University of California, Davis.

Step-by-Step Guide to Performing a Hydraulic Pressure Test

Safety First: Always consult your tractor's owner's manual before performing any tests. Always wear appropriate safety glasses and gloves. Ensure the tractor is turned OFF and the hydraulic system is depressurized.

- Preparation: Gather your kit, safety gear, and ensure the tractor is off and depressurized.

- Connection: Carefully connect the kit's hose to the appropriate hydraulic port, ensuring a secure, leak-free connection.

- Testing: Start the tractor and operate the hydraulic functions (lift arms, three-point hitch, etc.) observing the gauge readings. Compare readings to your tractor's manual specifications.

- Interpretation: Note any discrepancies. Low pressure can indicate leaks or pump problems; high pressure may suggest blockages or other issues.

- Disconnection: Shut off the tractor and allow the system to depressurize fully before disconnecting the test kit.

Maintenance and Calibration

Regular maintenance is crucial for ensuring the accuracy and longevity of your kit. Clean the gauge and hoses after each use. Calibration is recommended annually or more frequently depending on usage. Consider professional calibration for enhanced accuracy.

Troubleshooting Common Issues

- Gauge shows zero despite system pressure: Check connections for leaks or ensure the gauge is properly connected.

- Fluctuating readings: This might indicate an air leak in the system or a faulty sensor in the gauge.

A reliable hydraulic pressure test kit is an invaluable asset for maintaining your tractor. By choosing the right kit and following proper maintenance procedures, you can ensure your tractor's hydraulic system remains in peak condition, maximizing efficiency and minimizing downtime.